How to weld diamond saw blade by saw blade welding machine?

How to weld diamond saw blade by saw blade welding machine?

This Semi Automatic Diamond Saw Blade Welding Machine is used for Welding Diamond Circular Saw Blade from ø350mm to ø3500mm, Standard welded 2500mm saw blade ( Should be boosted 1000mm high). In addition, it also can be used for welding gang saw blade after specially modification, It is a new type of diamond saw blade welding auxiliary equipment. The Diamond Saw Blade Brazing machine Welding Rack has gripper, pneumatic sliding table and other high-precision components, thus greatly improving the welding accuracy and efficiency, to protect the segments and the base of the welding strength. Compared with similar welding machine with a high level of automation, positioning accuracy, stability, and long service life.This series of products using user-friendly design, general workers can operate on the machine.In addition, the welding machine compact structure, most of the wearing parts can be found and purchased in the pneumatic tools shop in your side, rather than relying on the service agents.

What is the diamond saw blade segments welding technique?

Boreway: There are three methods to weld and braze diamond segments onto the saw blade: silver brazed diamond blade, wholly sintered diamond blade and laser welded diamond blade.

1. Silver brazed diamond blade: diamond segments are brazed to the steel saw base using a silver solder. Silver brazed diamond blade can only be used in wet cuttings. If they are used in dry cuttings, the silver solder may melt under the high temperature generated in the dry cutting and the segments can break from the steel core and be extremely dangerous.

2. Wholly sintered diamond blade: the diamond blade is made by putting the steel core together with the diamond segments and the metal bond materials into a mold and then sintering them in a sintering machine.

3. Laser welded diamond blade: the laser melts the diamond segment and the steel core creating a stronger weld, which can hold the diamond segments even in high temperatures, so laser welded diamond blades can be used to cut many types of materials without water cooling.

What is laser welded diamond blade, how to distinguish it with other blades?

There are three kinds of welding method for diamond blade, including laser welded, sintered and high frequency welded. How to distinguish laser welded diamond blade with other saw blades? It is simple and easy by looking at where the diamond segments meet the core of the blade can help you getting a sense of which welding method was used.

When you look at that edge where the diamond segments meet the blade core, you will see a rough weld. It is not smooth or flat, it is jagged and rough. This is indicative of the laser welding process.

When you look at that edge where the diamond segments meet the blade core, you will see a rough weld. It is not smooth or flat, it is jagged and rough. This is indicative of the laser welding process.

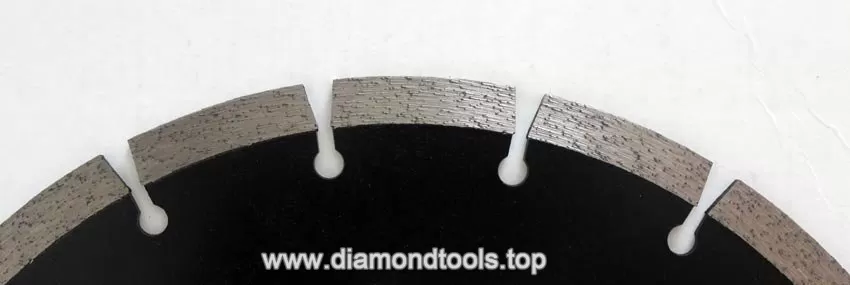

The following images are:

Laser welded diamond blades

High Frequency Diamond Saw blades -Use in Stone industry mainly

Sintered diamond saw blades, all the diameter less than 300mm/12inch

The main advantages and benefits of laser welded diamond blades over other welding methods are:

- the depth and width of the weld area is large.

- the weld is extremely accurate, so the blade core is very minimally affected.

- the depth and width of the weld area is large.

- the weld is extremely accurate, so the blade core is very minimally affected.

- The most important point is that the diamond segments would not drop during cutting.

- laser welded can withstand higher temperatures during cutting and extending blade life significantly.

- laser welded can withstand higher temperatures during cutting and extending blade life significantly.

Laser welded diamond blade is used in construction industry mainly, especially in concrete cutting. Some concrete contains steel bars, the temperature of diamond segments goes up quickly when cutting the steel bars in concrete, the diamond blade segments may drop, it is very dangerous to the operators. The disadvantage of laser welding diamond blade is that the diamond segments can not be replaced like high frequency welding blades when they are used up, and thus the cores are wasted.

Laser welding process of diamond saw blade

The diamond impregnated segments and the steel core were laser welded in a horizontal arrangement to achieve very high bond strength between them. A parametric investigation was conducted to evaluate the effect of several essential variables on high power laser beam welding, which include beam mode, power level, weld speed, focal point position, plasma suppression and beam alignment. The results showed that beam mode, power level, weld speed, plasma suppression along with focal point position are the primary parameters, which can influence the depth of penetration of laser welding. Beam alignment can greatly affect the amount of pores in the welded seam.

If you have any questions on any of the welds, please feel free to comment or email us directly.

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Latest posts

Search

Hot Product

Contact Us

![$curr_position[0]['banner'][0]->alt](https://v.zawl.cn/907/upload/image/20211101/214402-82.webp)